PRODUTS

Independent research and development, independent innovation

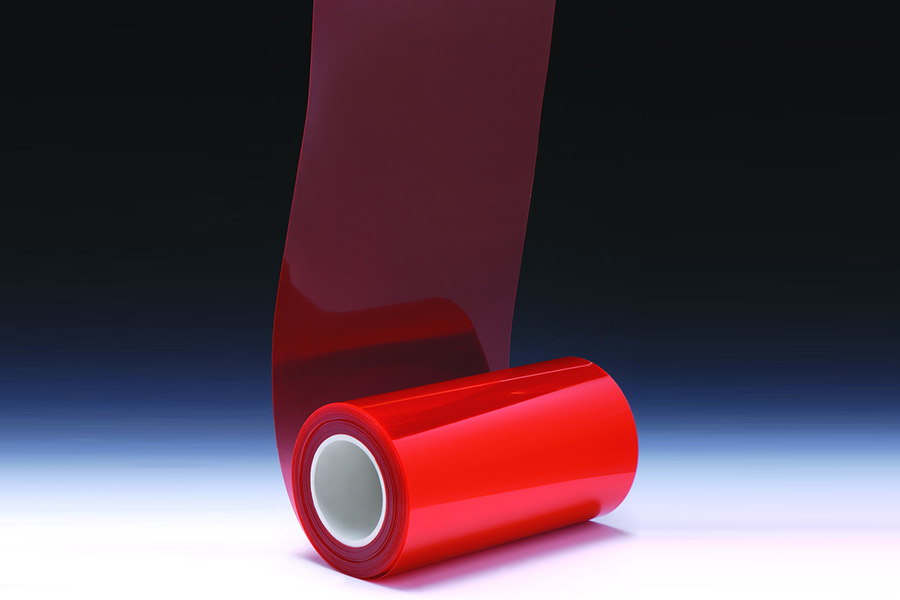

NO.1PVC rigid sheet for pharmaceutical packaging

SEE MORE >The use of rigid polyvinyl chloride (PVC pharmaceutical rigid sheet ) as a means of protecting drugs has been established for many years. PVC is used in PTP Al/plastic packaging to provide consumers with a wide range of benefits such as product visibility, barrier and mechanical protection, ease of use and adaptability. Polymer monolayer polyvinyl chloride films are commonly used in less demanding applications such as small tablets and superficial tablets. The copolymer grade PVdC is recommended for more demanding applications such as large tablets (Drugs with high moisture absorption). To solve requirements such as product performance and protection, such as childproof packaging and UV protection products, PVC sheets can provide suitable solutions.

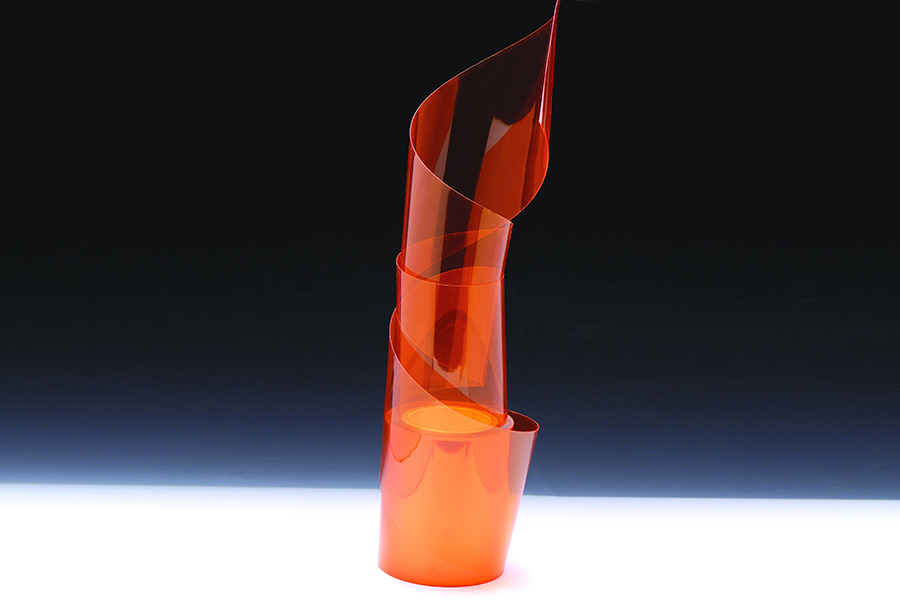

NO.2PVDC rigid sheet series for pharmaceutical packaging

SEE MORE >In order to provide the pharmaceutical market with more moisture protection, many enhanced performance protective ingredients can be added to PVC, polyester or other polymer substrates, such as PVdC (vinylidene chloride-based copolymer) coating film, it can provide high moisture-proof protection. Typically 40g, 60g and 90g/m2 coating weight on the market can lower the water vapor transmission rate (WVTR) from 0.6g/m2 to 0.2g/m2.

With the advent of new drugs and detection trends have emerged (40°C - 75% RH), and additional barrier performance requirements have steadily increased.

The development of our new PVDC series products can improve the barrier performance of PVDC, which will have a high barrier to water and oxygen, and has a very good protection for pharmaceuticals. Until now, our per B series PVDC has been able to achieve water vapor barrier properties of less than 0.1g/m2d.

NO.3Composite rigid sheet for food packaging

SEE MORE >Mainly based on PVC or PET rigid sheet, it is compounded with a variety of barrier materials. According to the different requirements of customers, we can design various structures to achieve the required barrier effect; it has certain rigidity and flexibility, and can be widely used in the packaging of various solid and liquid pharmaceuticals or foods. With the molding equipment, we can design a variety of different packaging shapes, which can be widely used in a variety of pharmaceutical orals, dairy products, candy, seasonings, beverages and other food packaging.

NO.4Commodity packaging rigid sheet

SEE MORE >It is mainly made of PVC or PET rigid sheet as base material, and is compounded with a variety of barrier materials. Various structures can be designed according to the different requirements of customers to achieve the required barrier effect. It has certain rigidity and flexibility, and can be widely used in the packaging of various solid and liquid daily necessities. With the the supports of canning equipment, it can design a variety of packaging shapes, which can be widely used in various perfumes, cleaning liquids, personal care packaging.

NO.5Composite rigid sheet for pesticide packaging

SEE MORE >It is mainly made of PVC or PET rigid sheet as base materials, and is compounded with a variety of barrier materials. It is designed to be used in a single quantity for consumers to make accurate ratios. After one-time use, it avoids the misuse and consumption of excess pesticides. It also designs different barrier types based on different components of pesticides, such as suspending agents, emulsions, phenyl groups, and alcohol groups. to ensures a good weight loss rate and achieves the ideal packaging effect.

MobileWeChat

MobileWeChat